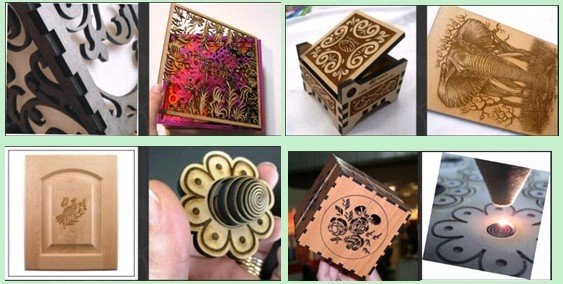

Laser Cutting machine

Equipment performance

1, Excellent precision ,quick speed.

2, Good rigid structure ,high stability

3, Machine tool movement adopt imported High-precision ball teaching screw linear guide.

4, The special moduled steel frame structure to reduce the mechanical trouble effectively, routeway feeding to satisfy material of different length.

5, Anodized aluminium lamella table

6, Industrial constant cooling system

7, Slide strut bar to support material forward to all directions.

8, Hydraulic protection control system

9, Inflatable protection control system,

10, The device of exhaust smoke and dust.

11, Invariable laser path (patent of sunic) is applied in the machine.

Optional configuration

Honey-comb worktable(for garment line), USB interface work offline; Touch screen control system,Step driver,Single ballscrew drive,Double linear guide drive.

Available Materials

Widely applied in cutting thick non-metallic material,it is suitable cutting thick Acrylic,Wood,Plastic,Bamboo,ABS and thin metal sheet, such as mild steel,stainless steel,aluminum board,copper foil and other related metal material.

Main technical parameters

|

Specification

|

SCC1313/SCC1318/SCC1325/SCC1825

|

|

Laser power

|

100W / 150W / 200W

|

|

Connecting way

|

PCI / USB online/offline reading U flash

|

|

Working platform size

|

1300×1300mm

1300×1800mm

1300×2500mm

1800×2500mm

|

|

cutting speed

|

≤1150 mm/s

|

|

Repeated accuracy

|

≤0.005mm

|

|

Minimum Line width

|

0.1mm

|

|

Cooling way

|

Water cooling

|

|

Power supply

|

220V / 50Hz / 2kVA

|